The Chinese electroacoustic industry has maintained a rapid development trend since the 1980s, and has now independently developed and mastered all production technologies from electroacoustic components to terminal electroacoustic products, forming a complete electroacoustic industrial system and related industry chain. So far, China has become the world's leading producer of earphones, resulting in a huge market share for domestic electroacoustic magnets.

In recent years, with the continuous development of digital products such as smartphones, tablets, laptops, portable media players, digital cameras, virtual reality devices (VR) globally and the large-scale international transfer of the electroacoustic industry, micro electroacoustic components and consumer electroacoustic products representing the high-end level of electroacoustics have rapidly developed in China.

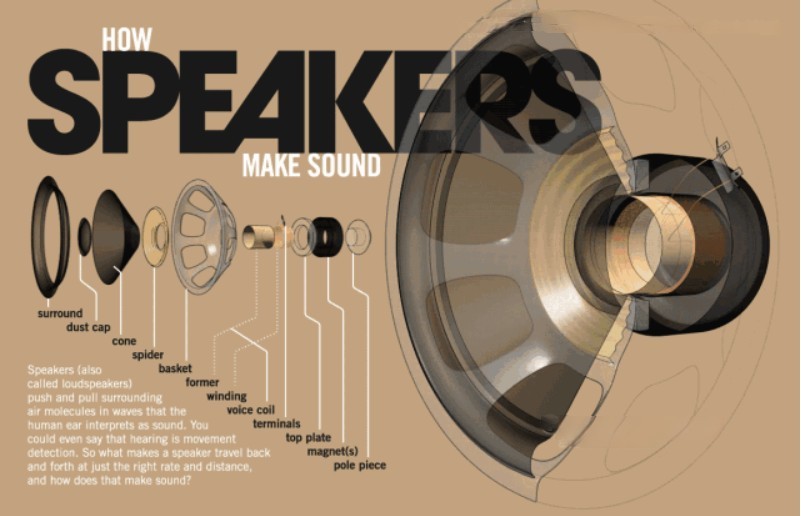

The core component responsible for producing sound in audio devices is the speaker, commonly known as the speaker. Whether it is the audio system or headphones, this key component is indispensable. A speaker is an energy conversion device that converts electrical signals into acoustic signals, and the performance of a speaker has a significant impact on the sound quality. To understand the magnetic properties of a horn, you first need to start with the sound producing principle of the horn.

A magnetic field is generated in the electrified wire, and the strength of the current affects the strength of the magnetic field (the direction of the magnetic field follows the right-hand rule). When AC audio current passes through the coil of the speaker (i.e. the voice coil), a corresponding magnetic field is generated in the voice coil according to the above principle. This magnetic field interacts with the magnetic field generated by the built-in magnet on the speaker, causing the voice coil to vibrate with the strength of the audio current in the speaker's magnetic field. The diaphragm and sound coil of the speaker are connected together. When the sound coil vibrates with the diaphragm of the speaker, it drives the surrounding air to vibrate, and the speaker produces sound. As shown in the figure, this is the principle of the horn.

When the volume of the magnet is the same and the voice coil is the same, the performance of the magnet has a direct impact on the sound quality of the horn:

The higher the magnetic flux density (magnetic induction intensity) B of a magnet, the stronger the thrust acting on the sound film.

The higher the magnetic flux density (magnetic induction intensity) B, the higher the relative power, and the higher the SPL sound pressure level (sensitivity).

Headphone sensitivity refers to the sound pressure level that can be emitted by the earphone when a sine wave of 1mw and 1khz is input to the earphone. The unit of sound pressure is dB (decibels). The higher the sound pressure, the higher the volume, so the higher the sensitivity, the lower the impedance, and the easier the earphones are to produce sound.

The higher the magnetic flux density (magnetic induction intensity) B, the lower the total quality factor Q value of the horn.

Q-factor refers to a set of parameters of the horn damping coefficient, where Qms is the damping of the mechanical system, reflecting the absorption and consumption of energy in the movement of various components of the horn. Qes is the damping of the power system, mainly reflected in the consumption of electrical energy by the voice coil DC resistance; Qts is the total damping, which is related to the above two as Qts=Qms * Qes/(Qms+Qes).

The higher the magnetic flux density (magnetic induction intensity) B, the better the transient.

Transients can be understood as "fast response speed" to signals, with relatively high Qms. A earphone with good transient response should respond immediately as soon as the signal arrives, and the signal should stop abruptly without any delay. For example, the transition from lead to ensemble is most evident in drum music and larger symphonies.

The horn magnets on the market mainly include three types: AlNiCo, ferrite, and NdFeB:

AlNiCo was the earliest used magnet for horns, such as horn horns from the 1950s and 1960s (commonly known as tweeters). Generally, it is made into an internal magnetic horn (external magnetic horn can also be used). Its disadvantages are small power, narrow frequency range, hardness and brittleness, and inconvenient processing. In addition, cobalt is a scarce resource, and the price of AlNiCo is relatively high. From a cost-effectiveness perspective, there are relatively few horn magnets that use AlNiCo.

Ferrite is generally made into an external magnetic horn, and its magnetic performance is relatively low. It requires a certain volume to meet the driving force of the horn, so it is generally used on larger volume audio speakers. The advantages of ferrite are its low price and high cost-effectiveness; The disadvantages are larger size, smaller power, and narrower frequency range.

The magnetic properties of NdFeB are far superior to AlNiCo and ferrite, making it the most commonly used magnet on horns, especially high-end ones. Its advantages are high magnetic performance under the same magnetic flux, small size, high power, lighter weight than other speakers, and wide frequency range. At present, HiFi earphones mainly use such magnets, which have excellent sound quality, elasticity, details, speech quality, and accurate sound field positioning. Its disadvantage is that it contains rare earth elements, resulting in higher material prices.

Contact: Cindy Wang

Phone: +86 19916725892

Tel: 0512-55128901

Email: [email protected]

Add: No.6 Huxiang Road, Kunshan development Zone, JiangsuShanghai Branch: No. 398 Guiyang Rd, Yangpu District, Shanghai, China