The difference between gear traction system and gearless traction system elevators

Toothless elevator traction machine and permanent magnet synchronous motor

Energy saving characteristics of NdFeB permanent magnet traction machine

advantages of NdFeB permanent magnet traction machine section

The earliest traction elevators emerged in the 20th century. The elevator includes components such as traction system, guidance system, gate system, car, balance system, electric drive system, power control system, and safety protection system. The working principle of a traction machine is similar to a pulley, where a steel wire rope or belt is hung on the traction machine, with one end connected to the elevator car and the other end connected to the lifting device. By controlling the traction of the steel wire rope, the height and operation of the elevator can be controlled.

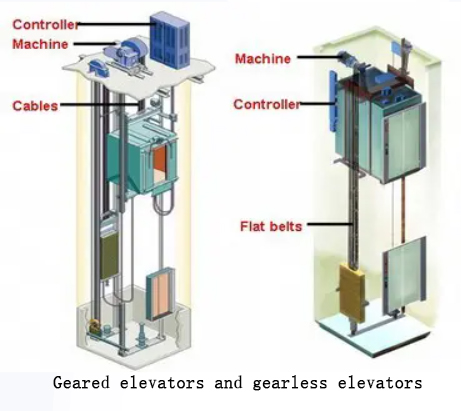

Traction elevators are usually divided into two types: gear traction and gearless traction. Gear traction controls the position of the elevator car through the rotation of the gearbox. Relatively speaking, gearless traction uses electromagnetic blocks to optimize the traction machine, eliminating the need for gear parts, resulting in a smaller volume. Compared with gear traction systems, gearless traction machines have the characteristics of smaller volume, higher efficiency, lower noise, environmental protection, and energy conservation. During the operation of the elevator, the stability and braking ability of the gearless traction machine are also better, therefore its practicality is higher. However, price cost is a factor, and if performance requirements are met, gear traction machines are usually considered a more economical option.

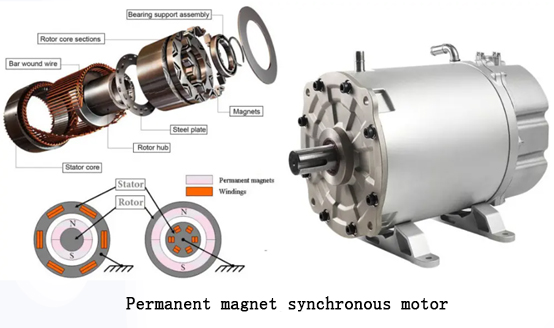

The elevator traction machine includes components such as an electric motor, traction wheels, and braking system. Compared to traditional induction motors, permanent magnet synchronous motors have replaced worm gear and worm structures, reducing mechanical transmission consumption by 70%. This can reduce the need for heat dissipation without the need for additional heat dissipation systems, greatly reducing the space occupied by the entire traction machine, and eliminating the need for a computer room. Permanent magnet synchronous motors are usually composed of high-performance NdFeB magnets such as N35SH, N38SH, N40SH, and N33UH, as well as special motor structures, which have the characteristics of low speed and high torque. A permanent magnet synchronous motor provides power for elevators and can be used as an electromagnetic block for elevator brakes, providing sufficient braking torque. It is an important basic part of the device to ensure elevator safety. Therefore, sintered NdFeB magnets are an important component of traction machines.

NdFeB magnet is the most widely used permanent magnet material in elevator traction machines. This type of magnet has the highest energy product among all available magnets and can produce compact and powerful motors. NdFeB magnets are made of a combination of neodymium, iron, and boron, which can be magnetized in any direction, making them versatile and easy to use.

The energy-saving technology of elevators is mainly reflected in two aspects: firstly, the elevator driving system adopts frequency conversion technology, and secondly, the driving system adopts NdFeB permanent magnet synchronous gearless traction technology. Elevator frequency conversion technology can save 25% of electrical energy compared to ordinary asynchronous motors.

According to calculations by the China Elevator Association, the average daily electricity consumption of each elevator in China is about 40kWh, accounting for about 5% of the entire building energy consumption. Elevators consume a huge amount of electricity and are one of the largest energy consuming equipment in high-rise buildings. Due to the application of rare earth permanent magnet NdFeB, elevator traction machines have the advantages of small size, low loss, high efficiency, and low noise, and have developed into the mainstream model of new traction machines, occupying the mainstream market position. The inorganic room elevator equipped with NdFeB permanent magnet synchronous traction machine technology is expected to control the energy consumption of the elevator in the entire building at around 3%.

The permanent magnet synchronous traction machine adopts multi pole low speed direct drive, without the need for a huge mechanical transmission efficiency of only about 70% of the worm gear and worm reduction gearbox; Compared with induction motor, it does not need to draw reactive current from the power grid, so the power factor is high; Due to the lack of excitation winding and excitation loss, the heat generation is small, so there is no need for a fan, no wind friction, and high efficiency; Adopting magnetic field oriented vector transformation control, it has the same excellent torque control characteristics as DC motors. The starting and braking currents are significantly lower than induction motors, and the required motor power and frequency converter capacity are reduced.

Low speed direct drive, resulting in low bearing noise, no fan, no worm gear noise. The noise can generally be reduced by 5-10 decibels to reduce environmental noise pollution.

Without a large reduction gearbox, excitation winding, and high-performance NdFeB permanent magnet material, the motor has a small volume and light weight, which can reduce or eliminate the need for a computer room.

The permanent magnet synchronous traction machine motor does not require brushes and collector rings, so it has a long service life and no oil or gas from the gearbox, resulting in less environmental pollution.

Compared with gear traction machines, the absolute advantage of permanent magnet synchronous traction machines in energy conservation and environmental protection has long been recognized in Europe and Japan, and has been discussed in the Chinese industry recently. In addition to the advantages that can be clearly recognized by the above clients, at the level of safety: due to its simplified structure and rigid straight axis braking, it provides full time up and down overspeed protection capability. In addition, it utilizes the anti electromotive force characteristics of permanent magnet motors to achieve the self-locking function of worm gears and worms, providing multi-layer safety protection for the elevator system and passengers. At the application level: Due to the miniaturization and thinness of permanent magnet synchronous traction machines, the arrangement of elevator configurations and the compatibility with the integrated space between buildings have greatly improved. It is believed that this provides architects with greater elastic design space and indirectly improves the functionality and quality of human use in building spaces.

Contact: Cindy Wang

Phone: +86 19916725892

Tel: 0512-55128901

Email: [email protected]

Add: No.6 Huxiang Road, Kunshan development Zone, JiangsuShanghai Branch: No. 398 Guiyang Rd, Yangpu District, Shanghai, China