Working principle of permanent magnet variable frequency air compressor

Energy saving effect of permanent magnet variable frequency air compressor

Permanent magnet variable frequency air compressor reduces production losses

Maintenance cost reduction of permanent magnet variable frequency air compressor

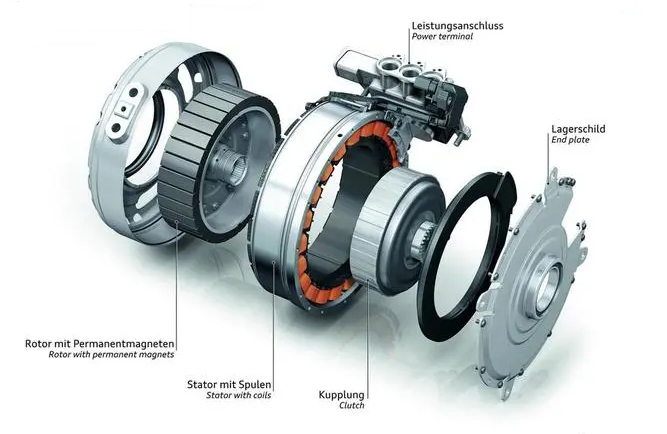

High efficiency NdFeB permanent magnet is the core component of a permanent magnet variable frequency air compressor, with a working temperature of 120 ℃ and no loss of magnetism. It has a long service life and good energy-saving effect. The working principle of the permanent magnet variable frequency air compressor is based on the rare earth element of the permanent magnet synchronous motor, which is the same as the electric excitation synchronous motor, except that the excitation winding is replaced by a permanent magnet for excitation. When the three-phase stator winding of the permanent magnet motor (each with a difference of 120° electrical angle) is connected with the three-phase alternating current of frequency f, a rotating magnetic field will be generated that moves at the synchronous speed. In the steady state, the main pole magnetic field and the rotating magnetic field rotate synchronously, so the rotor speed is also synchronous. The stator rotating magnetic field and the main pole magnetic field established by the permanent magnet remain relatively static. They interact with each other and generate electromagnetic torque, thus driving the motor to rotate and carry out energy conversion. The permanent magnet variable frequency air compressor adopts a permanent magnet rare earth permanent magnet synchronous motor (PM motor). The screw host and permanent magnet motor share the same main shaft, and the motor does not have bearings. The rotor with permanent magnet is directly installed on the extended shaft of the male rotor, with a transmission efficiency of 100%. This structure eliminates traditional motor bearing failure points and achieves maintenance free motor operation. Therefore, permanent magnet variable frequency air compressors have advantages such as long service life, maintenance free, and energy saving.

The variable frequency air compressor can automatically adjust the input voltage frequency according to changes in load, thereby maintaining the stability of main parameters such as working pressure, flow rate, and temperature, further improving the working performance of the air compressor. Compared to traditional air compressors, variable frequency air compressors have obvious advantages. It can effectively reduce the current surge during motor startup, reduce the impact on the customer's power grid, automatically adjust the load to reduce power consumption, reduce energy waste, and increase the service life of machine equipment. Therefore, variable frequency air compressors have many advantages.

The development of permanent magnet synchronous motors is closely related to the progress of permanent magnet materials. The emergence of new permanent magnet materials has greatly promoted the development of permanent magnet synchronous motors. In the 1980s, NdFeB rare earth permanent magnet materials were introduced. Due to the abundant resources of neodymium, iron replaced expensive cobalt at a relatively low price. nDfEb rare earth permanent magnet materials have excellent magnetic properties, and the improvement of these properties further promotes the research and application of permanent magnet synchronous motors.

The main advantage of permanent magnet variable frequency air compressors is energy conservation, which can generally achieve an energy-saving effect of 10% to 35%. The actual energy-saving level depends on the working status of the air compressor and the parameter settings of the frequency converter. Among them, the biggest influencing factor is the working condition of the air compressor. When the customer's gas consumption fluctuates greatly, the energy-saving effect is more significant, which is directly reflected in the proportion of idle time to total working time.

The permanent magnet variable frequency air compressor uses an energy-saving controller to simultaneously monitor up to 20 parameters, including current, voltage, speed, torque, electricity consumption, etc., achieving highly intelligent system control. This advanced control method improves the stability and reliability of the entire air compression system, reduces downtime, and reduces production costs and losses.

In the permanent magnet variable frequency air compressor, an energy-saving control system is adopted, which reduces the electrical impact on the motor electrical components during software startup, reduces the starting current, and prolongs the service life of the motor contactor. In addition, software startup also reduces the mechanical shock of equipment and extends the service life of mechanical parts such as motor bearings, host bearings and gearboxes.

The energy-saving controller control device keeps the air compressor in a loading state for most of the time, and various related solenoid valves and pneumatic components greatly reduce the number of actions, so the failure rate of both electrical and mechanical parts is greatly reduced. It has supported the cost of replacing parts and labor costs. In addition, the frequency converter control device keeps the air compressor in a loading state for most of the time, and the air inlet filter is always in a forward filtering state. When unloading, the air filter is in a reverse filtering state. The use of the frequency converter greatly reduces the reverse filtering time of the inlet filter and extends the service life of the filter element.

Permanent magnet synchronous motors have a series of advantages such as high efficiency, high specific power, simple structure, and significant energy-saving effects, which have been widely used in industrial production and daily life. With the successful development of high heat resistance and high magnetic performance NdFeB permanent magnets, as well as the further development and improvement of power electronic components, the research and development of rare earth permanent magnet synchronous motors have entered a new era at home and abroad, which will lead to a qualitative leap in theoretical research and application fields. At present, rare earth permanent magnet synchronous motors are constantly developing towards ultra-high speed, high torque, high-power, miniaturization, and high functionality.

The structure of permanent magnet synchronous motors is relatively simple, without the need for excitation windings, and there is no heat source in the magnetic field, so there is no need for cooling devices. At the same time, the motor uses materials with high coercivity, and the air gap length can also be taken as a larger value, which enables the motor to achieve high-speed operation.

The successful development of heat-resistant and high magnetic performance NdFeB permanent magnet materials will make them important applications in high-power permanent magnet synchronous motors. In various industries, such as transportation and industry, the demand for high-power electric motors is gradually increasing, such as electric vehicles, hybrid vehicles (including the combination of internal combustion engines and electric motors), trains, elevators, machine tools, robots, etc.

NdFeB permanent magnet materials have extremely high maximum magnetic energy product, especially being able to be made into ultra-thin permanent magnets, which enables the previously difficult to manufacture ultra micro and low inertia motors. At present, ultra small electric motors with a diameter of only a few millimeters have been developed as driving sources for medical micro machines, ophthalmic surgical robot arms, or pipeline detection. Even the world's smallest permanent magnet motor has been manufactured, with an outer diameter of only 0.8 millimeters and a length of 1.2 millimeters.

In special situations such as high temperature, high vacuum, or limited space, traditional motors are difficult to handle, while rare earth permanent magnet motors can withstand high temperatures (referring to samarium cobalt or high heat resistance NdFeB magnets) and have a small volume, which precisely meets these special requirements. For example, the application of robotic arms in aerospace equipment, inspection robots for atomic energy equipment, and electric motors for semiconductor manufacturing devices that need to work in special environments require the use of high-temperature motors and high vacuum motors. We have developed a three-phase four pole permanent magnet motor with a diameter of 105mm and a length of 145mm, using Sm2Co permanent magnet with excellent high-temperature characteristics. The motor has a power of 150W and a speed of 3000r/min, and operates in a high temperature environment of 200 ℃ to 300 ℃ and a vacuum degree of 133.3 X 10 Pa.

Contact: Cindy Wang

Phone: +86 19916725892

Tel: 0512-55128901

Email: [email protected]

Add: No.6 Huxiang Road, Kunshan development Zone, JiangsuShanghai Branch: No. 398 Guiyang Rd, Yangpu District, Shanghai, China