A permanent magnet crane is a lifting device that uses magnetic force to lift objects, without the need for power or other energy sources to drive. This type of crane has various names, such as magnetic crane, lifting magnet, magnetic crane, etc. Its characteristics include small volume, strong lifting capacity, high safety, and is very suitable for handling various steel materials, such as steel plates, iron blocks, cylindrical steel, mechanical parts, and punch molds.

To understand permanent magnet lifting appliances, it is first necessary to understand the basic knowledge of permanent magnet neodymium iron boron. Permanent magnets refer to magnets that can maintain magnetism for a long time, including natural magnets or artificial magnets. Natural magnets are formed by natural minerals under the influence of the Earth's internal magnetic field, while artificial permanent magnets have long-term magnetism through the processing of some metal alloy materials.

Neodymium iron boron is a rare earth raw material made from complex processes such as melting, cooling, crushing, and sintering with other metals, and then magnetized by a strong current to form a permanent magnet. The process is called magnetization. Permanent magnets made of rare earth materials have very stable performance.

The permanent magnet crane uses high-performance neodymium iron boron as the material, which generates strong suction in the magnetic circuit. The neodymium iron boron magnet can maintain a constant magnetic field after one magnetization, which is not easy to lose its magnetic force. This feature ensures that the crane can continuously and stably adsorb and suspend objects.

The permanent magnet crane has the characteristics of simple structure and easy operation. Control the lifting and lowering of the workpiece by rotating the control handle left and right. The magnetic core is composed of multiple neodymium iron boron magnetic iron blocks, which use their super strong magnetic force to lift workpieces and are the core components of the entire crane. The lifting ring is a device connected to a permanent magnet lifting device, with a V-shaped groove at the bottom providing greater contact area and preventing circular objects from rolling left and right. The function of the shell is to protect internal parts and assemble the entire product.

Safety is one of the most important considerations in the production process. Unlike other lifting equipment, permanent magnet hoists use magnetic attraction to lift products and do not generate magnetism on the products after lifting. To ensure safety during overloading, the pull-out force of the permanent magnet crane is 2-4 times the rated lifting capacity. It can easily lift several tons of products and handle 10 tons of heavy objects according to different specifications. During the lifting process, in order to prevent the handle from turning to the unloading state and causing the workpiece to fall off, the handle will be stuck by the safety bolt after turning to the working state. These designs help improve production safety.

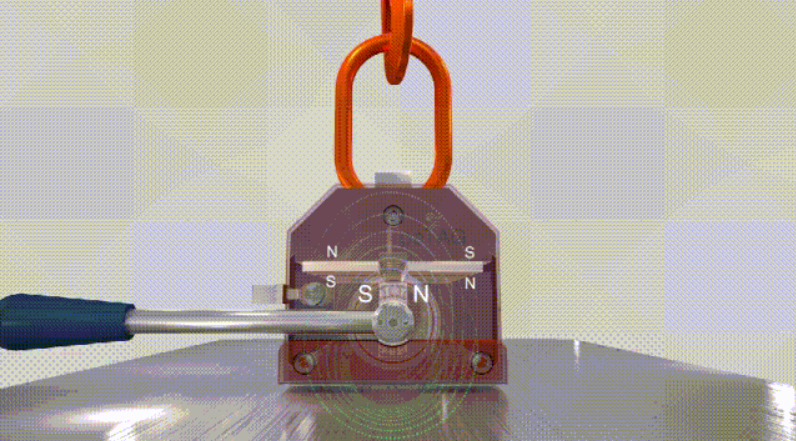

The working principle of the permanent magnet crane is based on the closed curve of the magnetic force line in the magnetic field and the superposition principle of the magnetic induction intensity. By rotating the handle to control the magnetic pole direction of the permanent magnet, the lifting device can be opened and closed. Unlike other devices, permanent magnet hoists can operate normally without the need for external power supply.

When the permanent magnet crane is in a stopped or unloaded state, the magnetic field line does not reach the working surface of the permanent magnet crane, but forms a closed circuit of the magnetic circuit inside the permanent magnet crane, consisting of a magnetic core and a top magnetic plate. Therefore, there are almost no magnetic lines of force exiting the working surface of the permanent magnet crane, which does not generate attraction to the object.

When you want the permanent magnet crane to be in working condition, simply rotate the handle 180 °;, and the magnetic pole direction of the entire magnetic core will change, causing the magnetic field line to come out from the N pole of the magnet, pass through the soft magnetic material transmission, pass through the iron plate or other iron parts, and finally return to the S pole of the magnet, forming a magnetic closed circuit, which firmly adsorbs the workpiece on the working surface of the permanent magnet crane.

Permanent magnet hoists have become a new direction in the field of lifting technology and an emerging field for the application of permanent magnet materials. This device does not require an external power supply and has the advantages of energy conservation, environmental protection, high suction force, and safety, effectively improving production efficiency and reducing processing time. With the continuous improvement of industrial requirements for energy conservation, environmental protection, efficiency improvement, and safety performance, traditional lifting appliances, electromagnets, and electromagnetic suction cups will gradually be phased out, and the development prospects of permanent magnet lifting appliances will be more broad.

Contact: Cindy Wang

Phone: +86 19916725892

Tel: 0512-55128901

Email: [email protected]

Add: No.6 Huxiang Road, Kunshan development Zone, JiangsuShanghai Branch: No. 398 Guiyang Rd, Yangpu District, Shanghai, China