Firstly, it is necessary to determine the production process of powder metallurgy gears: mold design and raw material determination - mold manufacturing - raw material mixing - mold installation and machine debugging production - pressing blank mesh belt furnace sintering - machining - heat treatment - deburring - rust prevention and oil immersion - inspection and qualified packaging.

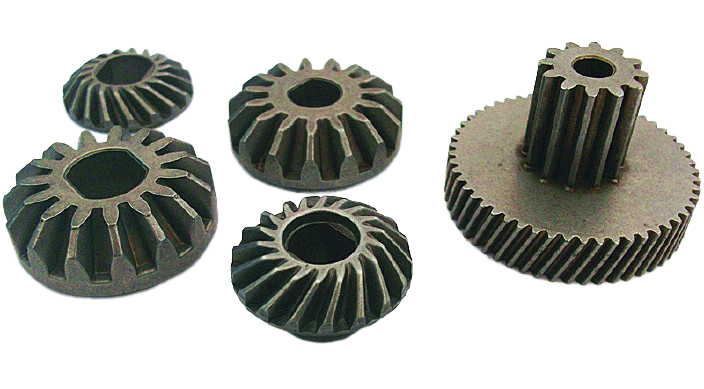

In the production and manufacturing of powder metallurgy gear teeth, the design of molds and production processes should be arranged in place. The material design of gears is very particular, and there are generally three types of material selection for powder metallurgy gears. FC0208, which is ordinary copper and carbon steel, is used to make some gears that are not very laborious, especially those made of plastic parts. In order to improve strength and accuracy, powder metallurgy gears are selected to reduce wear and fit accuracy, and noise will be reduced, Enhanced service life. There are also two types of pre alloy powders, FN0208 and FN0408, commonly known as AB alloy powder and AE alloy powder in the powder metallurgy industry. These two alloy materials are fully mixed by the manufacturer, and have good alloy properties, no segregation, stable composition, and can produce a pressing blank density of over 6.95. Warm pressing technology can also be used, and the pressing blank density can reach 7.2. After high-temperature sintering at 1120 degrees Celsius for 30 minutes, the metallographic bonding is strong and strong. AE alloy powder contains higher alloy components than AB alloy powder. In gear material selection with high strength requirements, powder metallurgy professionals must select materials appropriately based on relevant experience and material properties.

Powder metallurgy gears are quite important in the design aspect, and professional and experienced designers will optimize the teeth of the gears to increase their strength and limit without affecting their performance. Secondly, the seemingly simple powder metallurgy sintering process is also quite mysterious. When the powder metallurgy gear pre alloy powder is sintered at a temperature below 1120 and less than 30 minutes in the high-temperature zone, the alloy properties of the gear are not fully released, and its strength will be unsatisfactory.

Finally, the heat treatment hardness of powder metallurgy gears should be properly controlled. If it is too low, it is easy to have poor wear strength, and if it is too high and brittle, it will also affect strength. Each process of gear manufacturing sets inspection standards, and ultimately, BRM produces qualified and aesthetically pleasing powder metallurgy gear products.

Contact: Alexander Sun

Phone: +86 19916725893

Tel: 0512-55128901

Email: [email protected]

Add: No.6 Huxiang Road, Kunshan development Zone, JiangsuShanghai Branch: No. 398 Guiyang Rd, Yangpu District, Shanghai, China